Drive Productivity and Earn B-BBEE Points with On-Site Hose Repair.

For South African mining operations, the twin pressures of maximising productivity and ensuring stringent regulatory compliance are paramount. Every hour of downtime on a prime mover or excavator directly impacts production targets, while the mandates of the Mining Charter III demand strategic, impactful investments in economic transformation. The BOA Hydraulics solution is uniquely engineered to address both challenges simultaneously, offering a powerful pathway to operational excellence and B-BBEE compliance.

Operational Dominance in the Harshest Environments

The logistical challenges of mining—remote sites, harsh conditions, and the hours-long wait for external service technicians—make hydraulic hose failures particularly catastrophic. With the BOApod mobile hydraulic hose repair unit, you eliminate this dependency. This all-terrain, on-site workshop brings the factory to the field, enabling your team to assemble a new, permanent hose assembly in as little as 10 minutes.

Equipped with German-made Uniflex machinery and a stock of high-quality hoses and fittings, the BOApod ensures every repair meets the highest safety and quality standards required for the mining environment. This isn’t a temporary patch; it’s an OEM-quality solution that gets your multi-million-rand assets back to work immediately, transforming a 3-4 hour delay into a minor interruption.

A Strategic Solution for B-BBEE Enterprise and Supplier Development

The Mining Charter III and the B-BBEE Codes of Good Practice require mining companies to make significant contributions to Enterprise and Supplier Development (ESD). Finding relevant, sustainable, and impactful initiatives that also benefit your core operation is a major challenge. The BOA Hydraulics solution provides a direct and powerful answer.

By funding a local, black-owned SMME (with an annual turnover under R50 million, as stipulated by the guidelines) with a BOApod and a dedicated service contract, your mine can establish a fully compliant ESD beneficiary.

This single investment achieves multiple strategic goals:

Earns Priority ESD Points

Your contribution directly counts towards the Enterprise and Supplier Development element of your B-BBEE scorecard, a priority element that is critical for overall compliance.

Fulfils Procurement Targets

The newly established enterprise becomes a BEE-compliant service provider. Your procurement spend with this entity helps you meet the Charter’s target of sourcing 80% of services from South African BEE companies.

Secures Operational Uptime

You gain a dedicated, on-site hose repair service that is exclusively focused on your mine’s productivity, eliminating wait times and ensuring rapid response.

This innovative approach transforms a mandatory compliance expenditure into a strategic investment in your own operational resilience. It is the smartest way to meet your B-BBEE obligations while simultaneously driving productivity and profitability.

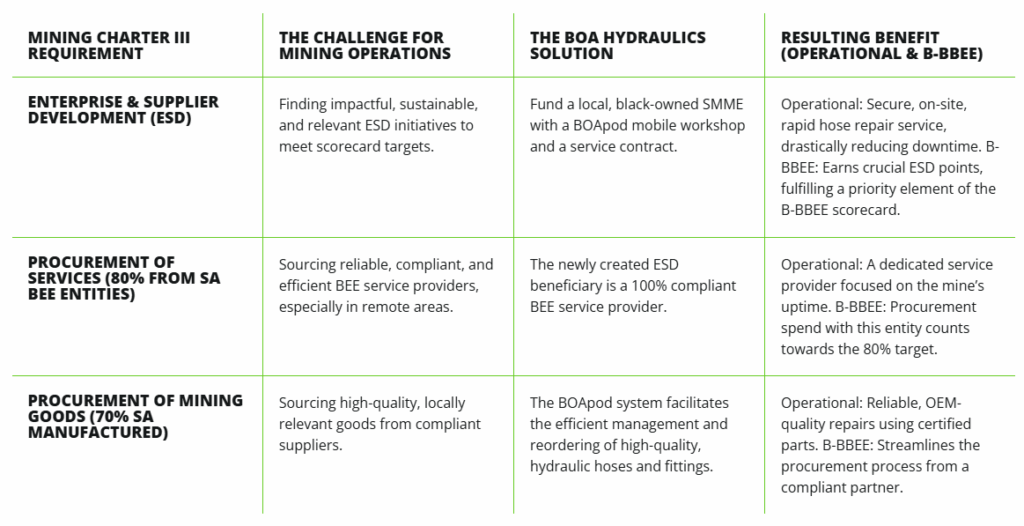

Mining Charter III Requirement

The Challenge for Mining Operations

The BOA Hydraulics Solution

Resulting Benefit (Operational & B-BBEE)

Enterprise & Supplier Development (ESD)

Finding impactful, sustainable, and relevant ESD initiatives to meet scorecard targets.

Fund a local, black-owned SMME with a BOApod mobile workshop and a service contract.

Operational: Secure, on-site, rapid hose repair service, drastically reducing downtime. B-BBEE: Earns crucial ESD points, fulfilling a priority element of the B-BBEE scorecard.

Procurement of Services (80% from SA BEE Entities)

Sourcing reliable, compliant, and efficient BEE service providers, especially in remote areas.

The newly created ESD beneficiary is a 100% compliant BEE service provider.

Operational: A dedicated service provider focused on the mine’s uptime. B-BBEE: Procurement spend with this entity counts towards the 80% target.

Procurement of Mining Goods (70% SA Manufactured)

Sourcing high-quality, locally relevant goods from compliant suppliers.

The BOApod system facilitates the efficient management and reordering of high-quality, hydraulic hoses and fittings.

Operational: Reliable, OEM-quality repairs using certified parts. B-BBEE: Streamlines the procurement process from a compliant partner.